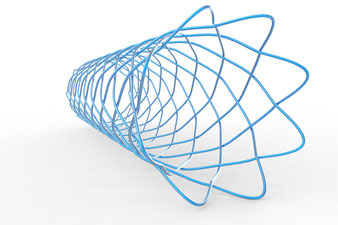

Stent design and FEA

Stent design (laser cut)

our strengths

- Stent conception

- Stent design (2D and 3D)

- Provide production drawings (laser cut DXF drawing)

Stent optimization and validation

The following parameters can be optimized:

- Radial force

- Flexibility in the vessel

- Distal and Proximal Stent side

- Crimp behavior

- Expansion behavior

- Fatigue

The following international standards are used in this context:

ISO 25539-1: Cardiovascular implants – Endovascular devices – Part 1: Endovascular prostheses

ISO 25539-2: Cardiovascular implants – Endovascular devices – Part 2: Vascular stents

ISO 25539-3: Cardiovascular implants – Endovascular devices – Part 3: Vena cava filters

ASTM F2514: Finite Element Analysis (FEA) of Metallic Vascular Stents Subjected to Uniform Radial Loading

ASTM F2477: Standard Test Methods for in vitro Pulsatile Durability Testing of Vascular Stents

ASTM F2942: Standard Guide for in vitro Axial, Bending, and Torsional Durability Testing of Vascular Stents

ASTM F3067: Guide for Radial Loading of Balloon Expandable and Self Expanding Vascular Stents

ASTM F2079: Elastic Recoil of Balloon-Expandable Stents

ASTM F3211: Fatigue-to-Fracture (FtF) Methodology for Cardiovascular Medical Devices.

FDA Guidance for Industry and FDA Staff: Non-Clinical Engineering Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systems. April 18, 2010

FDA Guidance for Industry and FDA Staff: Reporting of Computational Modeling Studies in Medical Device Submissions. September 21, 2016

Heart Valves:

ISO 5840-3: Cardiovascular implants – Cardiac valve prostheses – Part 3: Heart valve substitutes implanted by transcatheter techniques

ISO 5910: Cardiovascular implants and extracorporeal systems – Cardiac valve repair devices

Stent FEA (Braided and Lasercut)

We take the numerical proof of your stent and carry out the following simulations:

- Radial force (in the intended used area of the stent)

- Crimping (radially compressing up to catheter ID)

-

- Use heat treated material parameters (eg: NiTinol) !!!

- Expand (to the desired diameter)

- Stent fatigue (stent fatigue strength in the human vessel)

- Stent deployment (release)

- Stent foreshortening (axially compressing of the stent)

The following international standards and regulations are used in this context:

ISO 25539-1: Cardiovascular implants – Endovascular devices – Part 1: Endovascular prostheses

ISO 25539-2: Cardiovascular implants – Endovascular devices – Part 2: Vascular stents

ISO 25539-3: Cardiovascular implants – Endovascular devices – Part 3: Vena cava filters

ASTM F2514: Finite Element Analysis (FEA) of Metallic Vascular Stents Subjected to Uniform Radial Loading

ASTM F2477: Standard Test Methods for in vitro Pulsatile Durability Testing of Vascular Stents

ASTM F2942: Standard Guide for in vitro Axial, Bending, and Torsional Durability Testing of Vascular Stents

ASTM F3067: Guide for Radial Loading of Balloon Expandable and Self Expanding Vascular Stents

ASTM F2079: Elastic Recoil of Balloon-Expandable Stents

ASTM F3211: Fatigue-to-Fracture (FtF) Methodology for Cardiovascular Medical Devices.

FDA Guidance for Industry and FDA Staff: Non-Clinical Engineering Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systems. April 18, 2010

FDA Guidance for Industry and FDA Staff: Reporting of Computational Modeling Studies in Medical Device Submissions. September 21, 2016

Heart Valves:

ISO 5840-3: Cardiovascular implants – Cardiac valve prostheses – Part 3: Heart valve substitutes implanted by transcatheter techniques

ISO 5910: Cardiovascular implants and extracorporeal systems – Cardiac valve repair devices